News

Understanding Corrugated Flutes: How Structure Impacts Strength, Cost, and Print Quality

Why do some boxes perform better than others, even when they look the same?

The answer often lies inside — in the flute structure. Studies show up to 60% of a box’s compression strength comes from flute design, not just linerboard.

Flute Function: How It Works

Flutes act like miniature arches, giving corrugated boxes the ability to:

- Absorb vertical pressure during stacking

- Cushion products from shock and vibration

- Maintain rigidity while keeping weight low

Tip: Minor changes in flute structure can improve compression performance by 10–20% without increasing box size or paper grade.

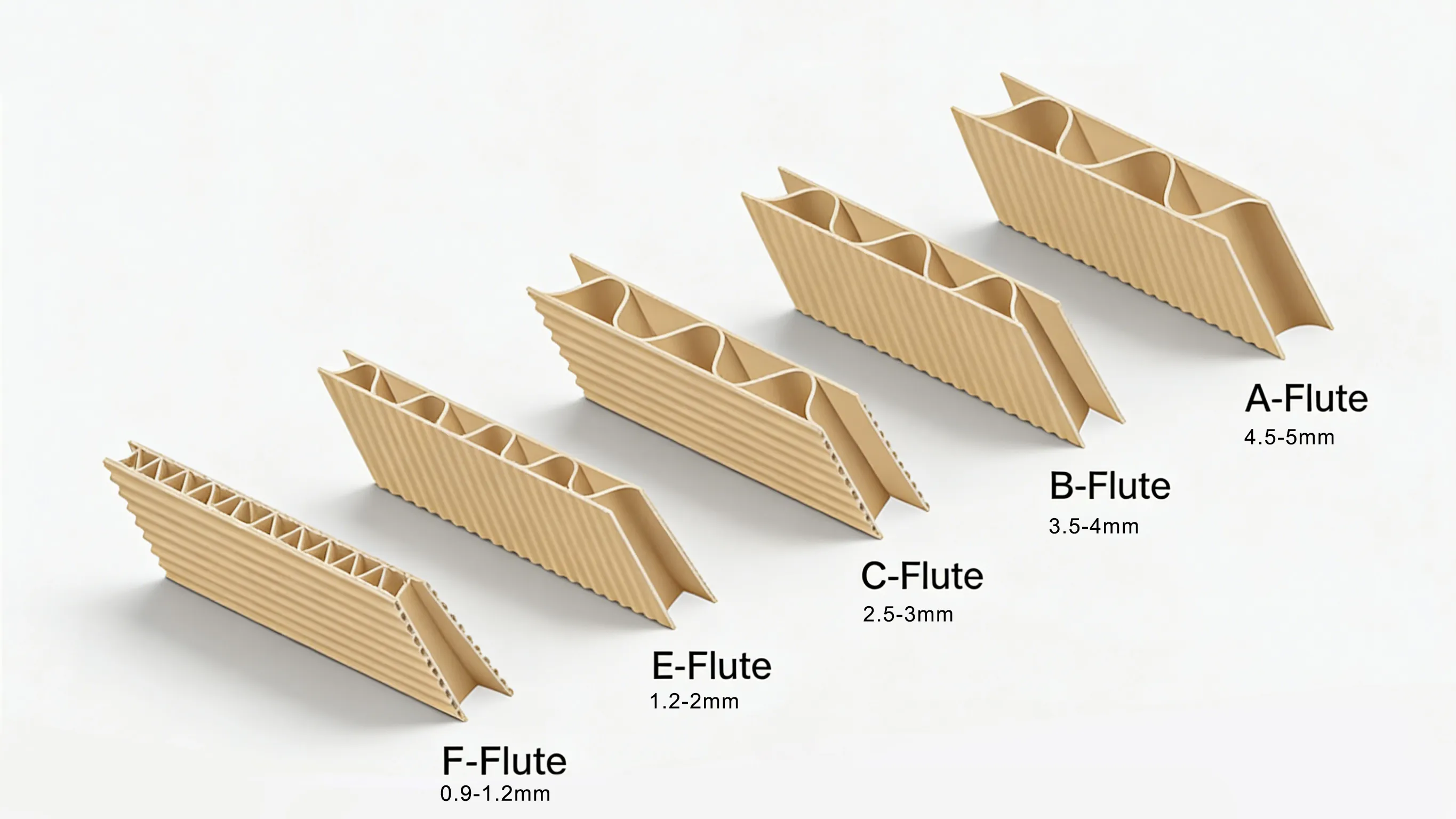

Common Flute Types

| Flute Type | Thickness | Key Trait | Typical Use |

|---|---|---|---|

| A / C | Thick | Cushioning & stacking | Fragile / heavy products |

| B | Medium | Crush resistance | Retail inserts |

| E / F | Fine | Smooth printing | E-commerce / premium packaging |

C-flute is the most widely used globally because it balances protection and material efficiency.

Performance Trade-Offs

Cushioning vs Space Efficiency

- Thick flutes (A, C) → better shock absorption, higher internal height, slightly higher shipping volume

- Fine flutes (E, F) → reduced box thickness, better pallet utilization

- Switching from C to E-flute can reduce box thickness up to 40%

Print Quality & Brand Presentation

- Coarse (A, C) → visible flute lines under heavy print

- Fine (E, F) → cleaner graphics & sharper text, ideal for retail-ready boxes

Tip: Combined flutes often outperform thicker paper alone, while keeping cost in check.

Choosing the Right Flute

Start with your product’s weight, fragility, stacking height, shipping distance, and branding requirements. Then select a flute type to balance protection, efficiency, and appearance.

| Priority | Recommended Flutes |

|---|---|

| Maximum protection | A, C, Double Wall |

| Cost efficiency | B, C |

| Premium appearance | E, F |

| Compact shipping | E, F |

Tip: The right flute selection reduces damage, shipping costs, and improves customer perception.

Wrapping Up & Next Step

Flutes may be invisible to customers, but they determine strength, efficiency, and brand impact. Align flute type with product, shipping, and visual goals for smarter, cost-effective packaging.

Ready to explore which flute and board combination works best for your products? Contact our packaging experts today to get personalized recommendations or request samples.

Why do some boxes perform better than others, even when they look the same?

The answer often lies inside — in the flute structure. Studies show up to 60% of a box’s compression strength comes from flute design, not just linerboard.

Flute Function: How It Works

Flutes act like miniature arches, giving corrugated boxes the ability to:

- Absorb vertical pressure during stacking

- Cushion products from shock and vibration

- Maintain rigidity while keeping weight low

Tip: Minor changes in flute structure can improve compression performance by 10–20% without increasing box size or paper grade.

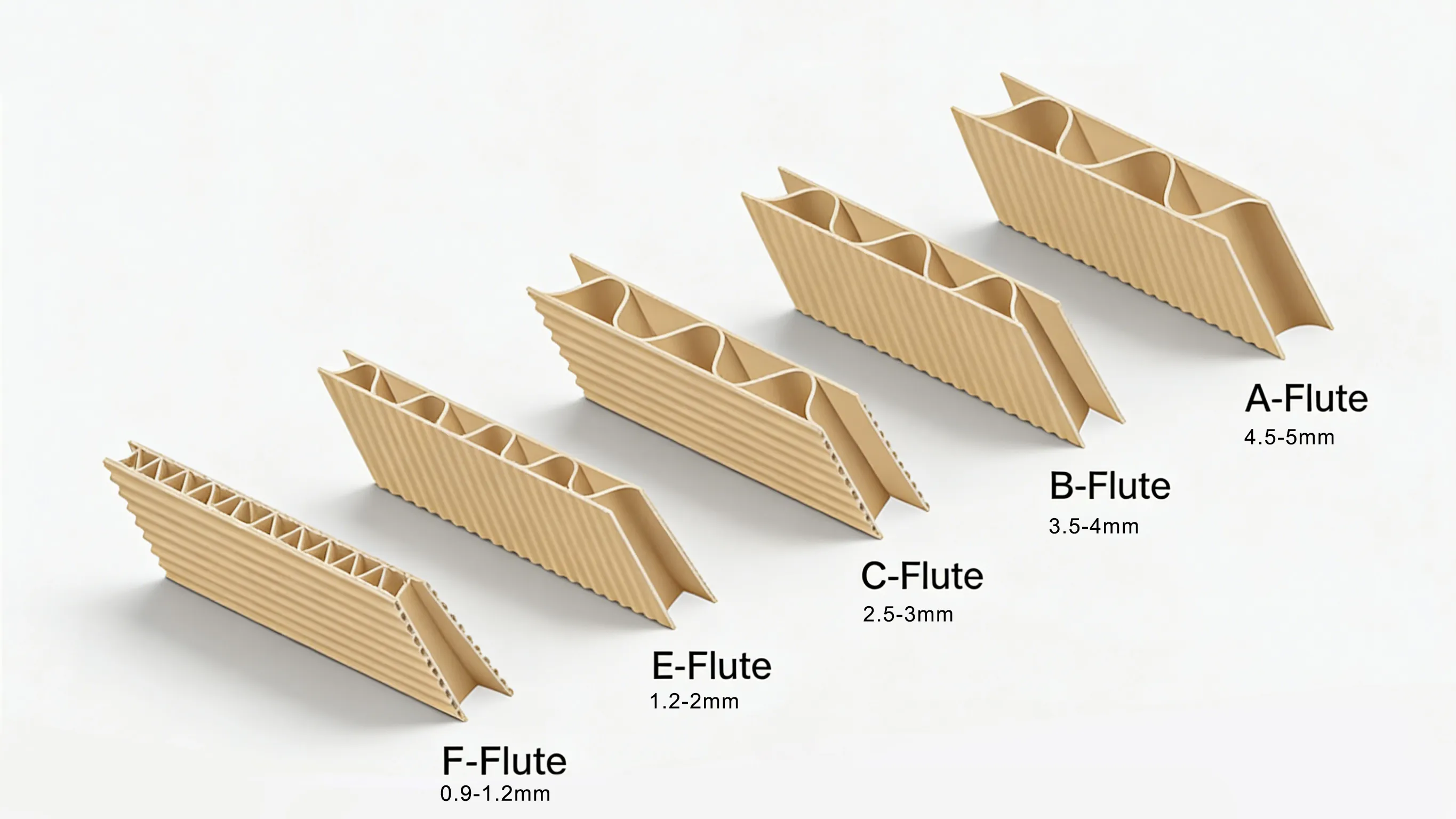

Common Flute Types

| Flute Type | Thickness | Key Trait | Typical Use |

|---|---|---|---|

| A / C | Thick | Cushioning & stacking | Fragile / heavy products |

| B | Medium | Crush resistance | Retail inserts |

| E / F | Fine | Smooth printing | E-commerce / premium packaging |

C-flute is the most widely used globally because it balances protection and material efficiency.

Performance Trade-Offs

Cushioning vs Space Efficiency

- Thick flutes (A, C) → better shock absorption, higher internal height, slightly higher shipping volume

- Fine flutes (E, F) → reduced box thickness, better pallet utilization

- Switching from C to E-flute can reduce box thickness up to 40%

Print Quality & Brand Presentation

- Coarse (A, C) → visible flute lines under heavy print

- Fine (E, F) → cleaner graphics & sharper text, ideal for retail-ready boxes

Tip: Combined flutes often outperform thicker paper alone, while keeping cost in check.

Choosing the Right Flute

Start with your product’s weight, fragility, stacking height, shipping distance, and branding requirements. Then select a flute type to balance protection, efficiency, and appearance.

| Priority | Recommended Flutes |

|---|---|

| Maximum protection | A, C, Double Wall |

| Cost efficiency | B, C |

| Premium appearance | E, F |

| Compact shipping | E, F |

Tip: The right flute selection reduces damage, shipping costs, and improves customer perception.

Wrapping Up & Next Step

Flutes may be invisible to customers, but they determine strength, efficiency, and brand impact. Align flute type with product, shipping, and visual goals for smarter, cost-effective packaging.

Ready to explore which flute and board combination works best for your products? Contact our packaging experts today to get personalized recommendations or request samples.