News

What is Corrugated Packaging and Why It Matters

When most people think of cardboard, they imagine a simple box.

In reality, corrugated board is an engineered material designed for protection, durability, and efficiency.

Even a standard single-wall box can withstand pressures of up to 40 kg/cm² before deformation. Add another layer, and stacking strength increases by roughly 50–70%, making double-wall boxes ideal for heavier or fragile items.

What Exactly Is Corrugated Board?

Corrugated board is a multi-layer structure designed for strength and protection. It is made of:

· Linerboard – the flat outer layers

· Medium – the fluted (wavy) inner layer that adds rigidity and cushioning

The combination creates a lightweight yet strong material.

For example, a typical C-flute single-wall box has enough cushioning to protect small electronics during transit, while an E-flute board reduces thickness for a sleeker retail presentation without sacrificing stability.

Corrugated vs. Cardboard: Why They’re Different

Many confuse corrugated board with regular cardboard, but the difference directly affects product protection:

| Material | Structure | Performance |

|---|---|---|

| Cardboard | Single, thick paperboard | Good for retail packaging, not for shipping |

| Corrugated Board | Multiple layers + fluted core | Strong, protective, ideal for shipping & e-commerce |

If you need shipping strength, corrugated is the right choice.

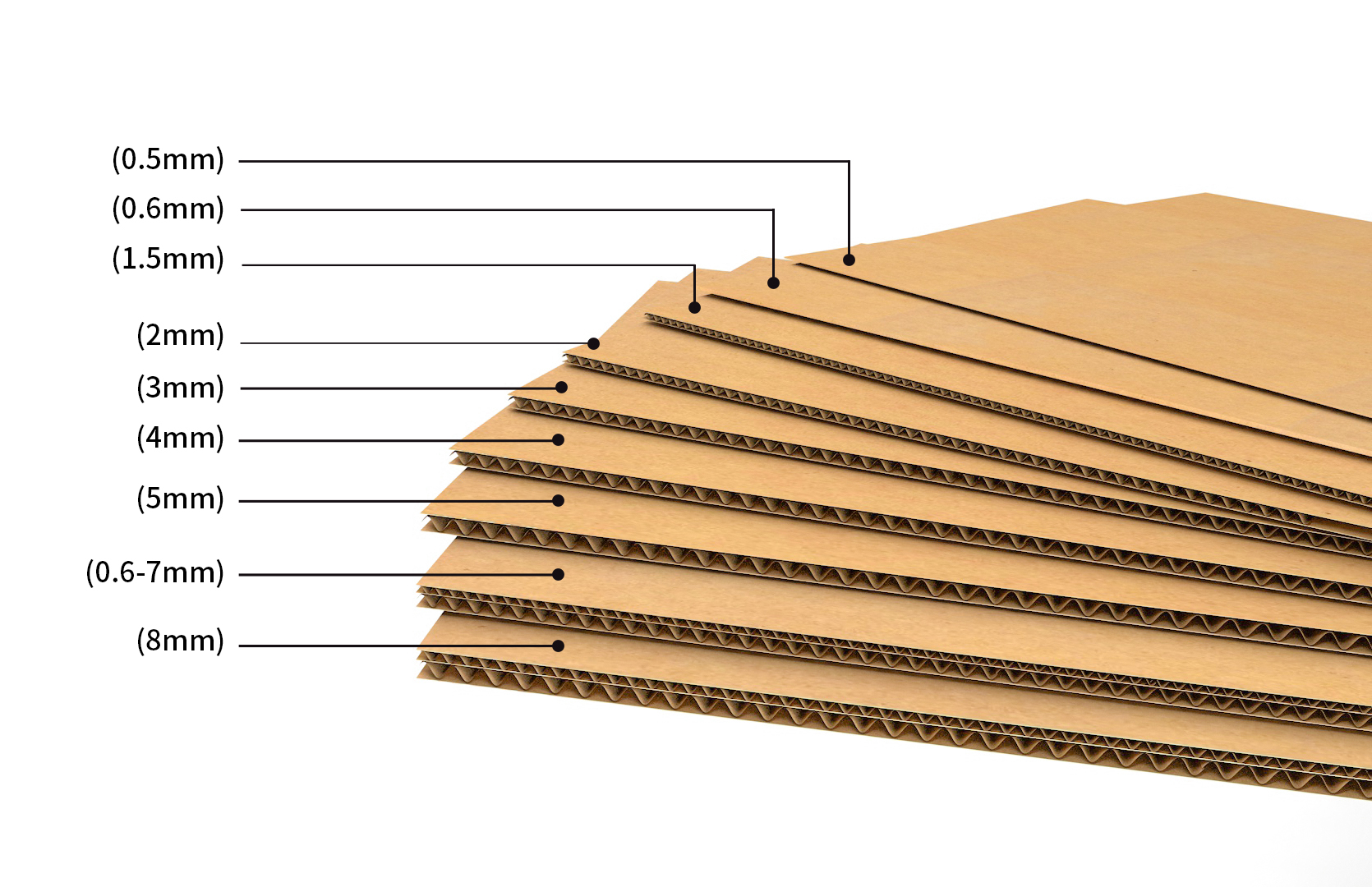

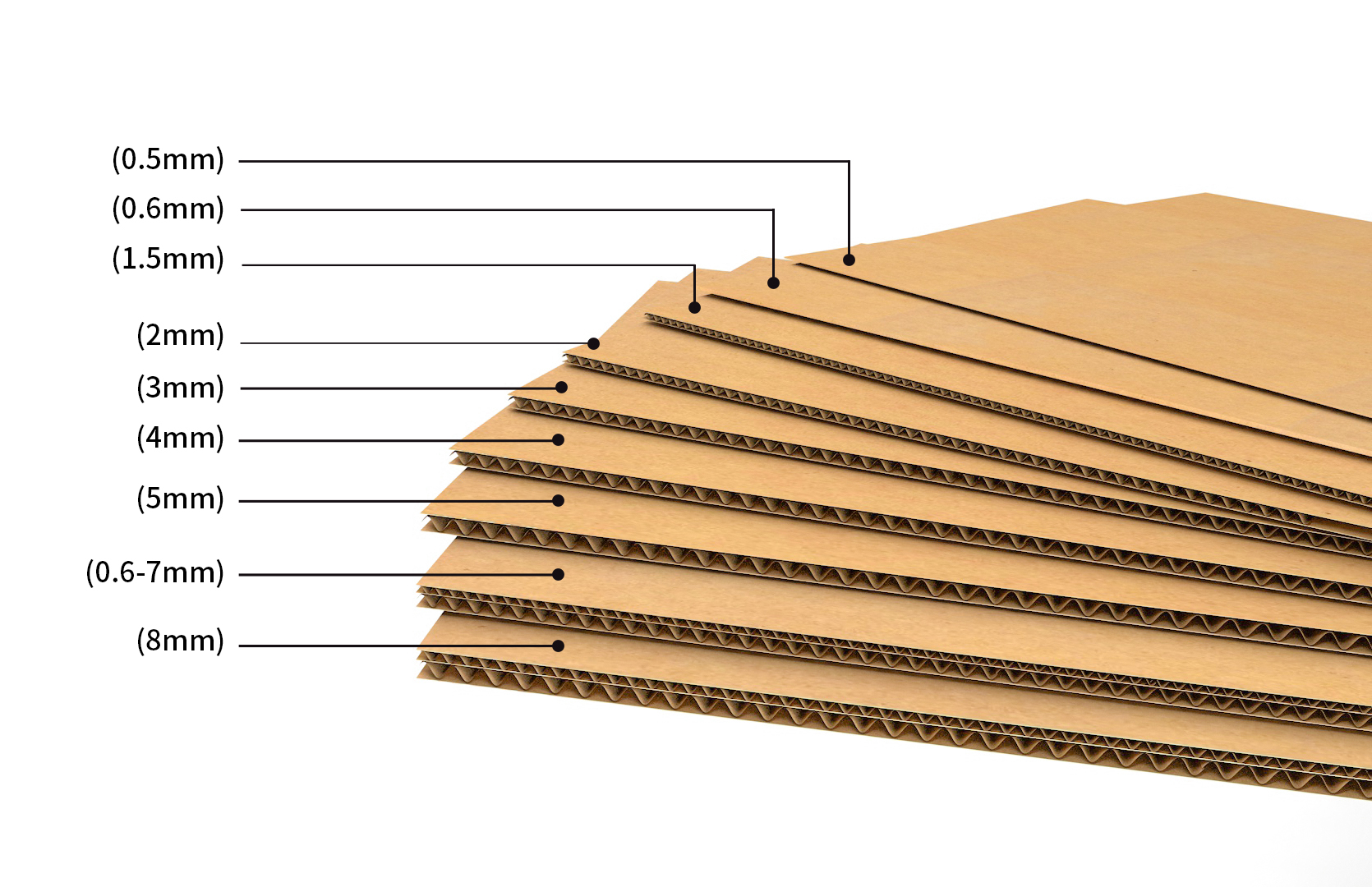

Single, Double, Triple: Layer Selection

| Board Type | Layers | Strength Increase | Best Use Cases |

|---|---|---|---|

| Single-wall | 3 | Base strength | Light to medium products, standard shipping |

| Double-wall | 5 | +50–70% |

Fragile items, mid-weight products |

| Triple-wall | 7 | 100+% | Heavy-duty shipments, long-distance export |

Tip: More layers = more protection, but also more weight and shipping cost. The key is balancing safety with cost.

Why Brands Prefer Corrugated

Corrugated board delivers:

· Protection: Absorbs impact and prevents crushing

· Lightweight & Efficient: Strong yet easy to handle, keeping shipping costs competitive

· Customizable: Sizes, flute types, printing, and finishes

· Sustainable: Fully recyclable and biodegradable

The combination creates a lightweight yet strong material.

Quick Insight Box:

Small adjustments in board thickness or flute type can improve cushioning performance by 10–20%, reducing product damage and returns.

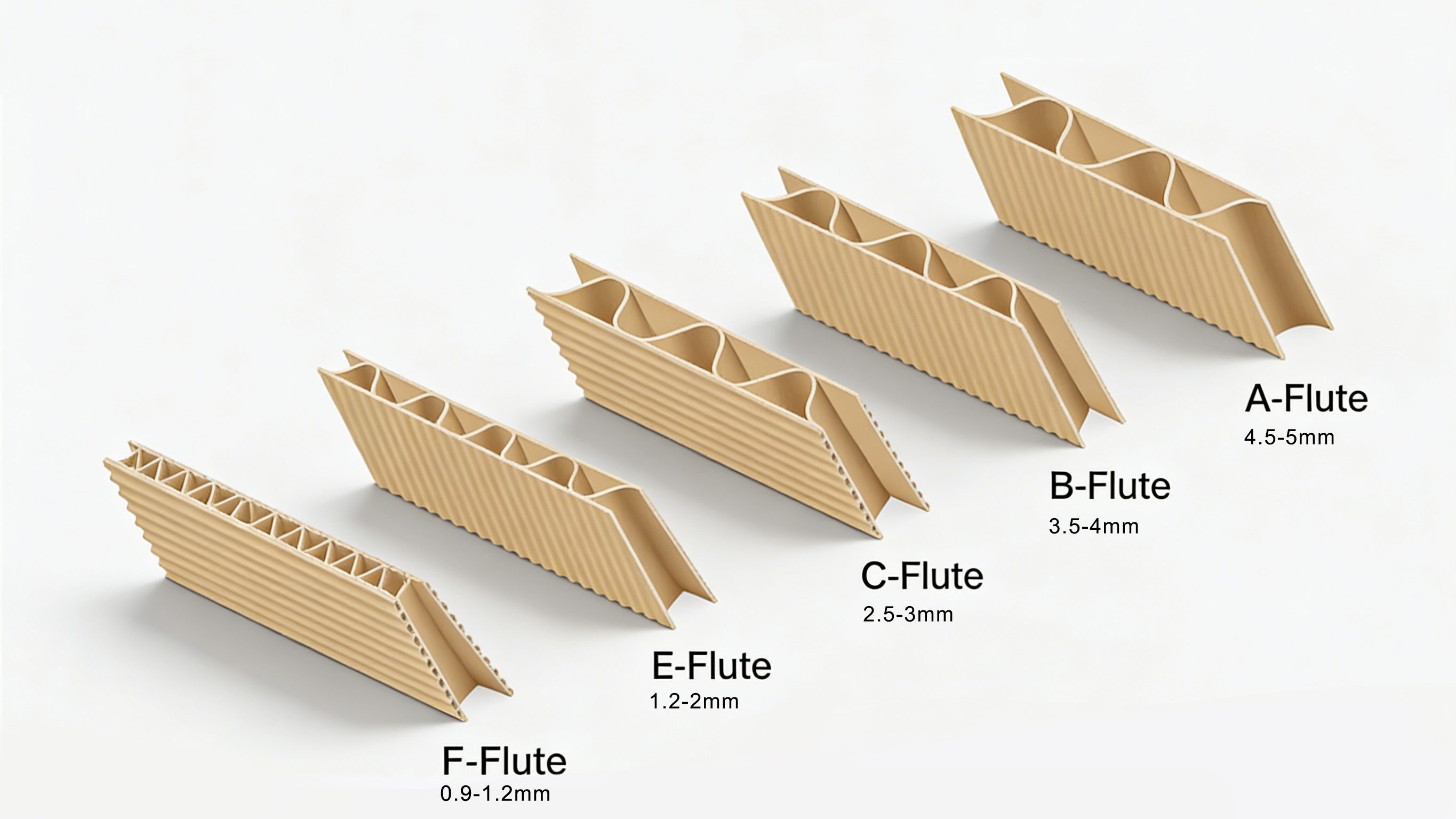

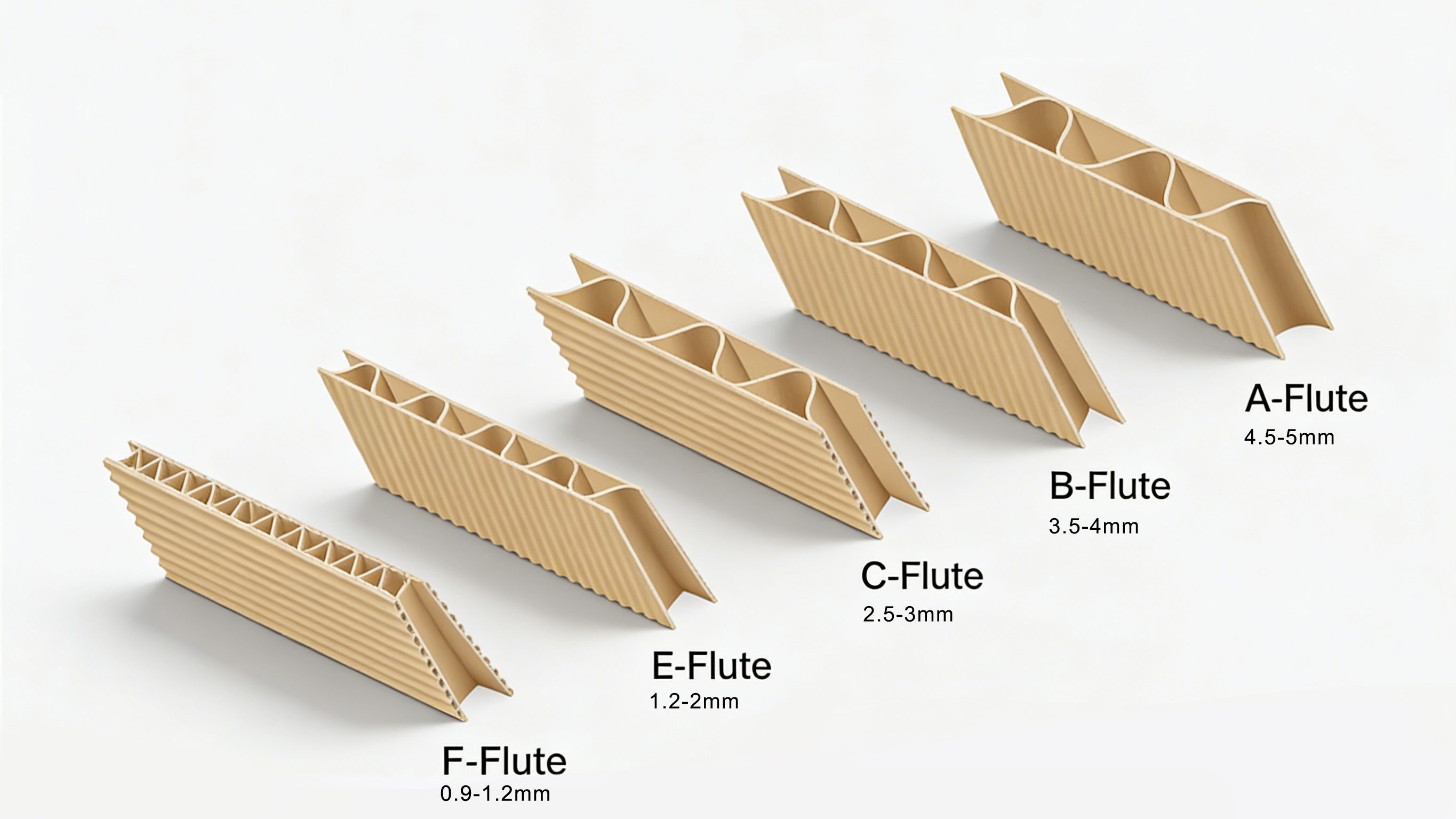

Next Step: Understanding Flutes

The next critical factor in corrugated board is the flute type — the wavy layer inside the board that impacts both strength and appearance.

| Flute Feature | Effect |

|---|---|

| Thick flutes | Higher cushioning & stacking strength |

| Fine flutes | Smoother surface for premium printing |

Tip: Evaluate your product’s weight, fragility, and shipping conditions first — the right combination of board construction + flute type sets the foundation for safe, attractive packaging.

Wrapping Up

Corrugated packaging is more than just a box — it’s a carefully engineered solution that protects your products, improves shipping efficiency, and supports your brand image.

Understanding the basics of board construction and layers ensures that your packaging decisions are both practical and cost-effective.

Ready to explore which flute and board combination works best for your products? Contact our packaging experts today to get personalized recommendations or request samples.

When most people think of cardboard, they imagine a simple box.

In reality, corrugated board is an engineered material designed for protection, durability, and efficiency.

Even a standard single-wall box can withstand pressures of up to 40 kg/cm² before deformation. Add another layer, and stacking strength increases by roughly 50–70%, making double-wall boxes ideal for heavier or fragile items.

What Exactly Is Corrugated Board?

Corrugated board is a multi-layer structure designed for strength and protection. It is made of:

· Linerboard – the flat outer layers

· Medium – the fluted (wavy) inner layer that adds rigidity and cushioning

The combination creates a lightweight yet strong material.

For example, a typical C-flute single-wall box has enough cushioning to protect small electronics during transit, while an E-flute board reduces thickness for a sleeker retail presentation without sacrificing stability.

Corrugated vs. Cardboard: Why They’re Different

Many confuse corrugated board with regular cardboard, but the difference directly affects product protection:

| Material | Structure | Performance |

|---|---|---|

| Cardboard | Single, thick paperboard | Good for retail packaging, not for shipping |

| Corrugated Board | Multiple layers + fluted core | Strong, protective, ideal for shipping & e-commerce |

If you need shipping strength, corrugated is the right choice.

Single, Double, Triple: Layer Selection

| Board Type | Layers | Strength Increase | Best Use Cases |

|---|---|---|---|

| Single-wall | 3 | Base strength | Light to medium products, standard shipping |

| Double-wall | 5 | +50–70% |

Fragile items, mid-weight products |

| Triple-wall | 7 | 100+% | Heavy-duty shipments, long-distance export |

Tip: More layers = more protection, but also more weight and shipping cost. The key is balancing safety with cost.

Why Brands Prefer Corrugated

Corrugated board delivers:

· Protection: Absorbs impact and prevents crushing

· Lightweight & Efficient: Strong yet easy to handle, keeping shipping costs competitive

· Customizable: Sizes, flute types, printing, and finishes

· Sustainable: Fully recyclable and biodegradable

The combination creates a lightweight yet strong material.

Quick Insight Box:

Small adjustments in board thickness or flute type can improve cushioning performance by 10–20%, reducing product damage and returns.

Next Step: Understanding Flutes

The next critical factor in corrugated board is the flute type — the wavy layer inside the board that impacts both strength and appearance.

| Flute Feature | Effect |

|---|---|

| Thick flutes | Higher cushioning & stacking strength |

| Fine flutes | Smoother surface for premium printing |

Tip: Evaluate your product’s weight, fragility, and shipping conditions first — the right combination of board construction + flute type sets the foundation for safe, attractive packaging.

Wrapping Up

Corrugated packaging is more than just a box — it’s a carefully engineered solution that protects your products, improves shipping efficiency, and supports your brand image.

Understanding the basics of board construction and layers ensures that your packaging decisions are both practical and cost-effective.

Ready to explore which flute and board combination works best for your products? Contact our packaging experts today to get personalized recommendations or request samples.